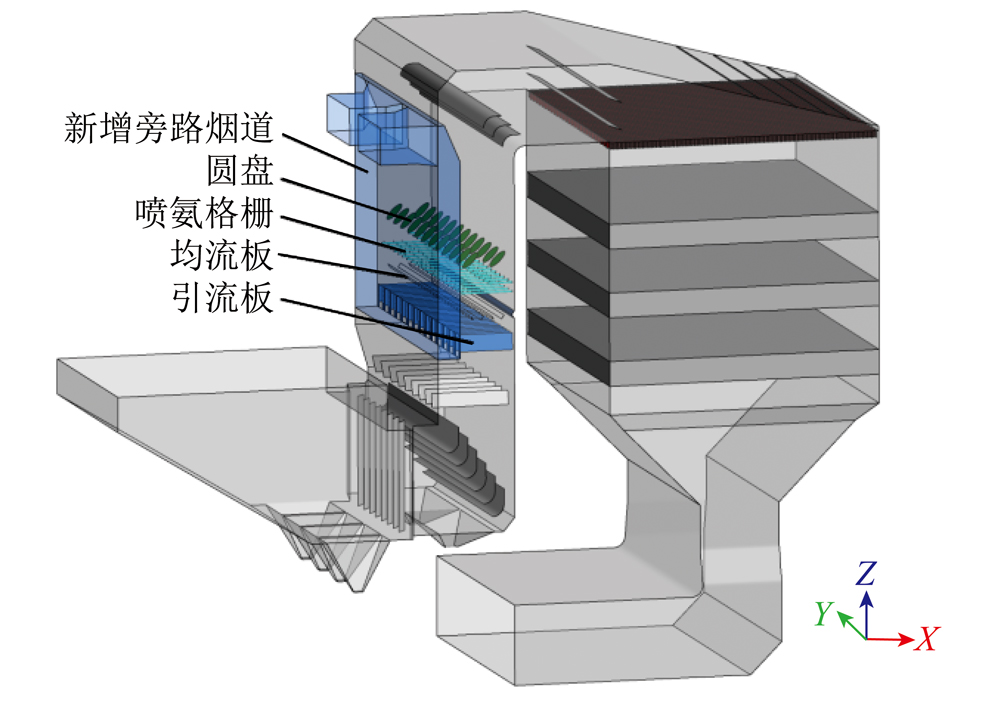

With the transformation and upgrading of China′s energy structure, more and more coal-fired power plants have been operating in the medium-low load range for a long time, which exposes the problem that the inlet flue gas temperature of SCR-DeNOx can not meet catalyst requirement at low-load operation. And the flue gas bypass modification is a flexible and efficient method to improve the gas temperature. Taking the wide load denitrification gas bypass reconstruction project of a 600 MW unit as an example,the design difficulties and flow field problems of bypass flue under limited construction space were discussed by using the numerical simulation method, and a kind of optimal design ideas were put forward. The results show that: After program analysis, the main difficulties caused by space limitation mainly include two aspects: short mixing distance between main flue gas and by-pass flue gas, and the unfavorable uniformity of NH3/NOx distribution. After program optimization, the flow field distribution in the SCR denitration system is greatly improved, and the relevant flow field technical indexes can be satisfied whether the bypass flue is put into operation or not. Especially when the bypass flue is put into operation, the relative standard deviation of NH3/NOx distribution at inlet of the 1st layer catalyst is decreased from 20.5% under initial plan to 3.7%, and the temperature deviation is reduced from -21.6-51.5 ℃ under initial plan to -13.8-9.5 ℃. A series of measures such as separating a part of the main flue as the bypass flue, adopting the form of smoke return with small passage and guide plate, and placing the AIG and mixer downstream of the bypass smoke return can significantly improve the flow field distribution uniformity, which is an important reference significance to wide-load SCR-DeNOx project.

Optimal design of high temperature bypass flue for wide-load SCR-DeNOx device under limited space

2022 No. 07

2022 No. 07

417

417 277

277

Authors:

- ZHANG Chucheng

- YE Xinglian

- LIU Dongdong

- SU Yinbiao

- YANG Ding

- LUO Kun

Unit:

- College of Energy Engineering,Zhejiang University;Fujian Longking Co.,Ltd.,

Abstract:

Keywords:

- SCR-DeNOx

- flue gas bypass reconstruction

- low load operation

- temperature deviation

- flow field optimization

Citation format:

张楚城(1991—),男,福建龙岩人,硕士研究生。E-mail:fj_zcc@163.com

通讯作者:罗坤(1977—),男,河南信阳人,教授,博士生导师,博士。E-mail:zjulk@zju.edu.cn

通讯作者:罗坤(1977—),男,河南信阳人,教授,博士生导师,博士。E-mail:zjulk@zju.edu.cn

Chart:

Articles:

--

Citation format:

--

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors