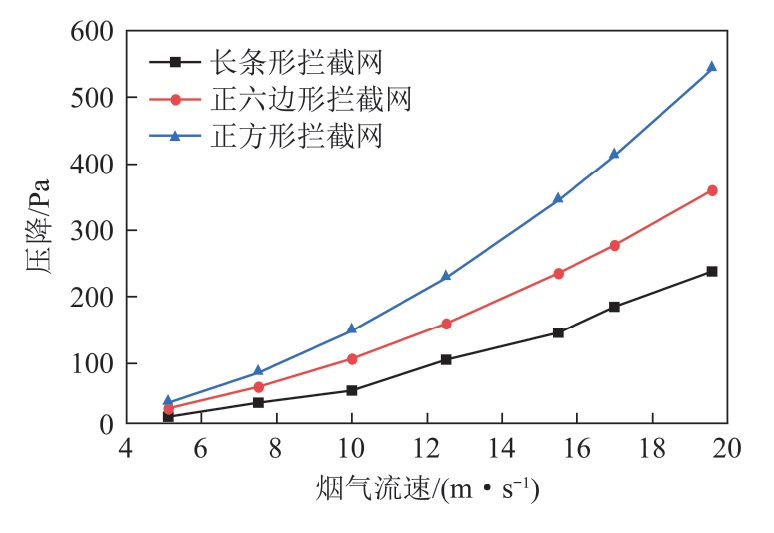

The large ash particles in the flue gas from coal combustion would lead to severe blockage and wear problems of the catalyst in a selective catalytic reduction (SCR)denitrification system,which affects the service life and denitration performance of SCR catalyst. This problem can be effectively solved by installing an interception net device in the flue to intercept large particle ash. The design of interceptor mainly depends on experimental measurement and engineering experience,which lacks general design criteria and theoretical basis,and the research on influence factors of pressure drop is not deeply explored. It is of significance for developing an effective and low-cost interceptor to calculate accurately the pressure drop of the flow across the interceptor with different pore structures. The influences of pore structure,flue gas velocity,interceptor porosity and thickness on the pressure drop were investigated based on computational fluid dynamics by construct the calculation model of interceptor mesh. The simulation results show that controlling parameters on pressure drop are the flow velocity and the porosity. The pressure drop is a quadratic power function of the flow velocity within the range of 5-20 m/s and inversely proportional to the third power of the porosity when the porosity of the interception network is 40%-65%. It is also found that,given the same porosity,the pore structure has negligible effect on the pressure drop. And the strip interceptor has the minimum pressure drop under the condition of the same critical size. The pressure drop increases quasi-linearly with the thickness of interceptor increase in the range 6-18 mm. Based on a large number of simulation data,A correlation is then proposed to predict the pressure drop and the empirical expression of the equivalent porous medium permeability of the interception network is further deduced,which can be feasibly applied to full-scale CFD simulation of SCR denitrification system.

Pressure drop characteristics of large particle ash interceptor in SCR flue gas denitrification system

2022 No. 06

2022 No. 06

568

568 298

298

Authors:

- MENG Lei

- LEI Yu

- CHEN Sheng

- LIU Xiaowei

- YUE Pujie

- GU Xiaobing

Unit:

- Datang Environment Industry Group Co.,Ltd.,;State Key Laboratory of Coal Combustion,Huazhong University of Science and Technology

Abstract:

Keywords:

- selective catalytic reduction

- large particle ash

- interceptor

- CFD simulation

- permeability

Citation format:

孟磊(1985—),男,山西定襄人,高级工程师,博士。E-mail:mengl@dteg.com.cn

通讯作者:陈晟(1992—),男,浙江杭州人,副研究员,博士。E-mail:sheng_chen@hust.edu.cn

通讯作者:陈晟(1992—),男,浙江杭州人,副研究员,博士。E-mail:sheng_chen@hust.edu.cn

Chart:

Articles:

--

Citation format:

--

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors