Fluidized bed technology: challenges and prospects in CCS anddecarbonization applications

2025 No. 03

2025 No. 03

342

342 151

151

Authors:

- LU Yong

- LI Lin

- SUN Zhengkun

- DUAN Lunbo

Unit:

- Key Laboratory of Energy Thermal Conversion and Control of Ministry of Education,school of energy and environment,Southeast University

Abstract:

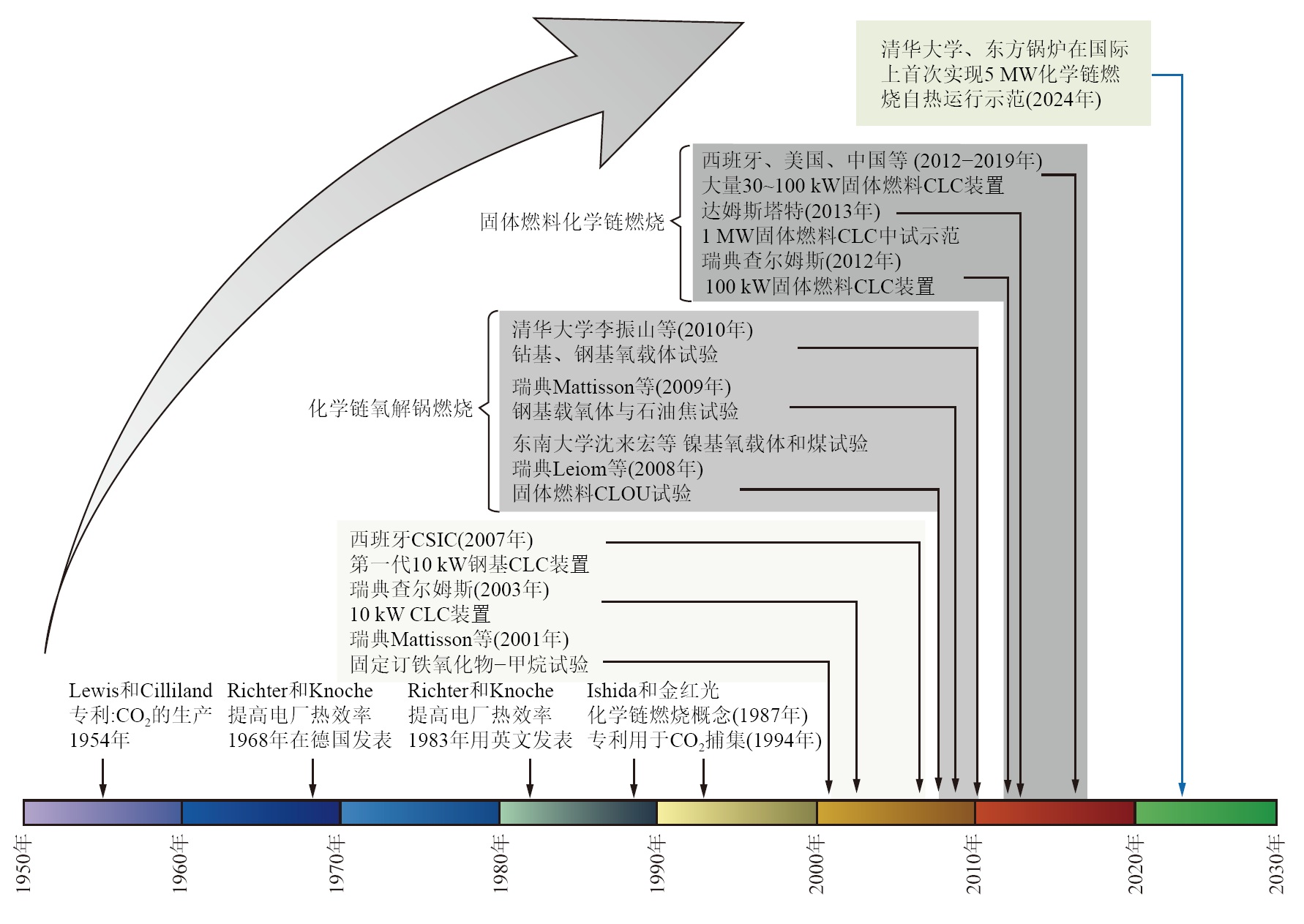

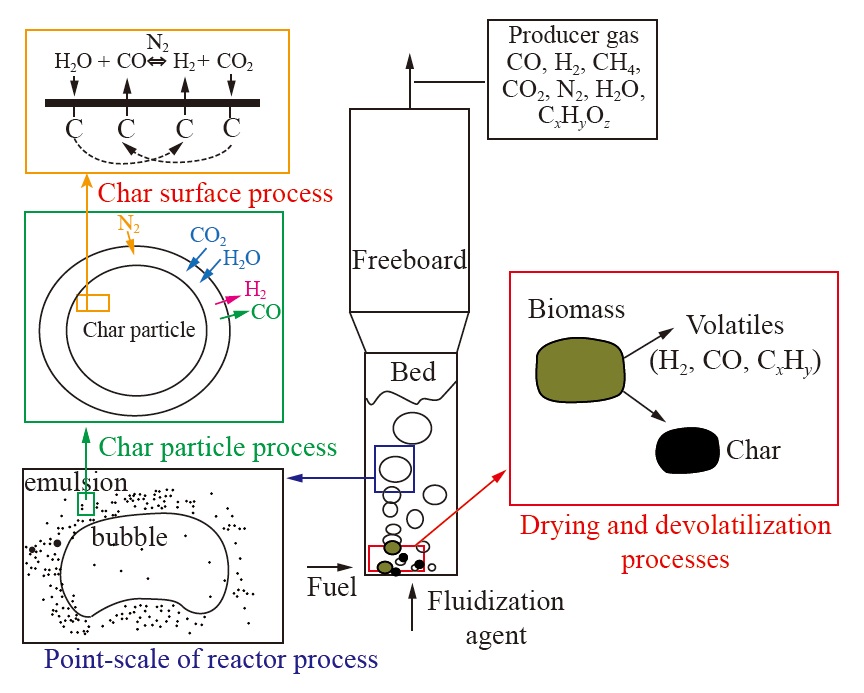

Fluidized bed reactors (FBRs),with their superior heat/mass transfer efficiency,operational flexibility,and scalability,haveemerged as a cornerstone technology for carbon capture and storage (CCS) and industrial decarbonization. This reviewcomprehensively analyzes the advancements of FBR applications across pre-,mid-,and post-combustion carbon capture stages. In pre-combustion,FBRs enable efficient fuel gasification into syngas,enhanced by calcium-based adsorbents for CO2 separation; mid-combustion techniques,including oxy-fuel combustion and chemical looping combustion (CLC),leverage fluidization dynamics to achieve flue gas CO2 concentration exceeding 80%; post-combustion capture relies on calcium looping (CaL) and alkali-basedadsorbent cycles,capitalizing on FBRs’ continuous operation for high-efficiency CO2 adsorption-regeneration. Innovations integrat- ingsolar and electric heating further expand FBRs’ decarbonization potential:solar-driven calcination coupled with CaL reduces CO2emissions from fossil fuel combustion and decreases energy consumption by 30%,while electric heating offers precise temperature controlfor zero-carbon processes like biomass gasification and cement calcination. However,challenges persist in scaling FBRs,includingadsorbent degradation (e.g.,40% activity loss in CaO after 10 cycles resulted from the collapse of pore structure and surfacepassivation),equipment erosion (SiC coatings reduce wear by 70% but require optimization),high energy demands (calcination at900-950 ℃),and process integration complexities (e.g.,dynamic coordination in CLC multi-reactor systems and circulation factor ofoxygen carriers). To achieve carbon neutrality,future research must prioritize:1) developing stable adsorbents (e.g.,nano-modifiedCaO,MOFs); 2) designing multi-stage reactors (e.g.,bubbling-transport coupled systems) for optimized mass/heat transfer; 3)integrating CFD multi-scale modeling with AI-driven real-time control; and 4) fostering cross-disciplinary innovations,such as plasmaheating and microwave-assisted regeneration. Policy support should focus on carbon pricing mechanisms,pilot funding,and internationalstandardization. By synergizing renewables,smart technologies,and material science,FBRs could drive deep decarbonization in power,cement,and steel industries,offering an economically viable and sustainable pathway for global energy transition.

Keywords:

- FBRs

- CCS

- decarbonization technologies

- solar energy

- electric heating

Citation format:

陆勇(1960—),男,江苏江阴人,教授,博士。E-mail:dyonglu@seu.edu.cn

Chart:

Articles:

--

Citation format:

LU Yong,LI Lin,SUN Zhengkun,et al. Fluidized bed technology: challenges and prospects in CCS and decarbonizationapplications[J].Clean Coal Technology,2025,31(3):1−16.

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors