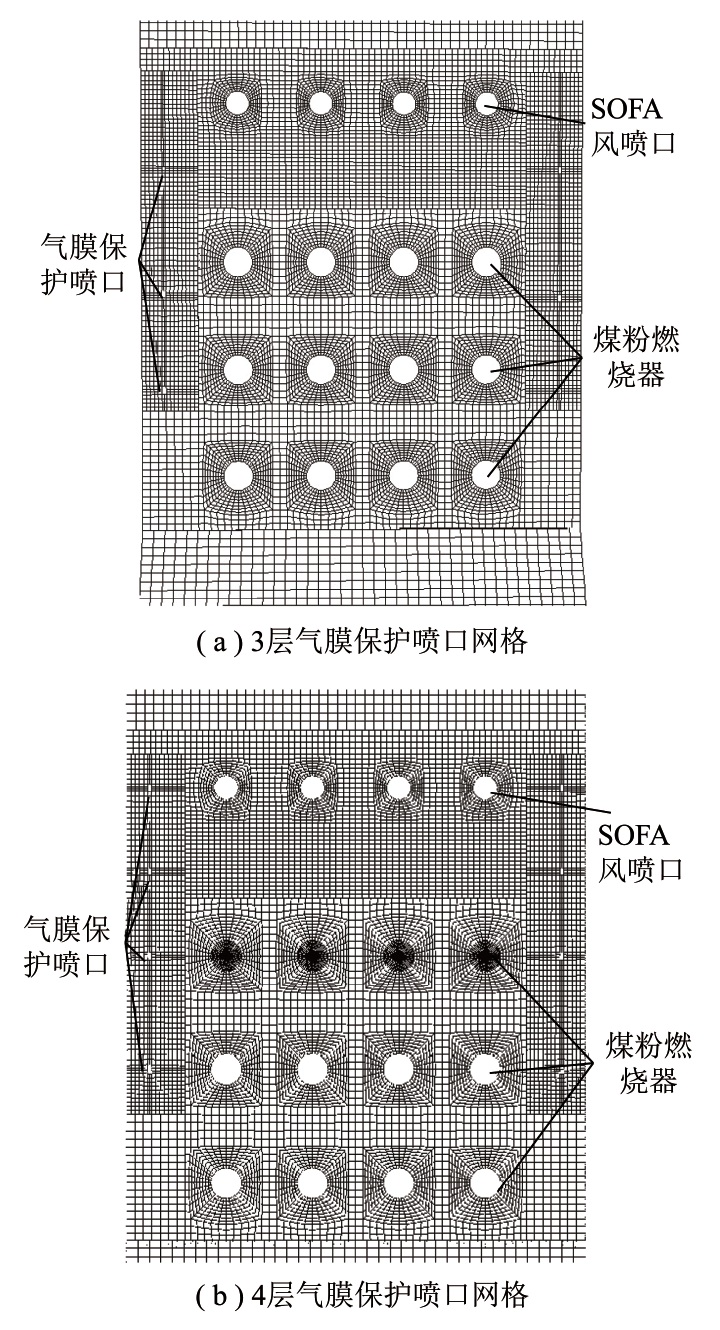

After the ultra-low emission transformation of domestic coal-fired unit boilers, there are varying degrees of high-temperature sulfur corrosion problems in the boiler water wall, especially the opposed combustion boiler, which seriously threaten the safe and stable operation of the boiler.In order to fundamentally solve the problem of high temperature sulfur corrosion of water wall, an air membrane protection technology was proposed to prevent high temperature sulfur corrosion of opposed combustion boiler water wall. The numerical calculation software was used to simulate and calculate the flue gas composition near the water wall during boiler operation. Taking the volume fraction of O2, CO and H2S components in the flue gas as the main research object, the position, number of layers, vertical inclination and air volume ratio of the air membrane protection nozzle were optimized, and the research results were compared and verified through the on-site verification test.The numerical calculation research and field test results show that after the application of air membrane protection technology, the changes of boiler thermal efficiency and NOx volume concentration at the inlet of SCR denitration reactor are insignificant, and the boiler operation parameters are normal, which will not have an adverse impact on the normal operation of the boiler.After the application of air membrane protection technology, the average volume fraction of O2 near the water wall can reach more than 5.0%, which is more than 5 times higher than that before application, and the average volume fraction of H2S can be reduced by more than 85% compared with that before application, which can be controlled below 100 μL/L.The reducing atmosphere in the area near the water wall is eliminated and the concentration of corrosive gas H2S is significantly reduced.The high-temperature sulfur corrosion ofwater wall can be fundamentally treated and the safety of boiler operation is significantly improved.The air membrane protection technology of water wall has a good demonstration effect on the prevention and treatment of high temperature sulfur corrosion of boiler water wall of the same type of unit.

Air membrane protection technology for water wall of opposed combustion boiler

2023 No. 06

2023 No. 06

519

519 335

335

Authors:

- PENG Zonggui

- SUN Jun

- LIAN Lingxian

- SU Fangwei

- LIU Yongsheng

- DU Zhihua

- MENG Xinyu

- SHAN Hengjie

- GUO Wenhai

- PENG Longfei

Unit:

- Huaneng Qinbei Power Generation Co.,Ltd.,

- Xi′an Thermal Power Research Institute Co.,Ltd.,

Abstract:

Keywords:

- air membrane protection technology

- opposed combustion boiler

- water wall

- high-temperature corrosion

- reducing atmosphere

- corrosive gas

Citation format:

彭宗贵(1980—),男,安徽芜湖人,高级工程师,硕士。E-mail:pengzonggui@sohu.com

通讯作者:孙军(1987—),男,天津人,高级工程师,硕士。E-mail:sunjun@tpri.com.cn

通讯作者:孙军(1987—),男,天津人,高级工程师,硕士。E-mail:sunjun@tpri.com.cn

Chart:

Articles:

--

Citation format:

PENG Zonggui,SUN Jun,LIAN Lingxian,et al.Air membrane protection technology for water wall of opposed combustion boiler[J].Clean Coal Technology,2023,29(6):151-160.

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors