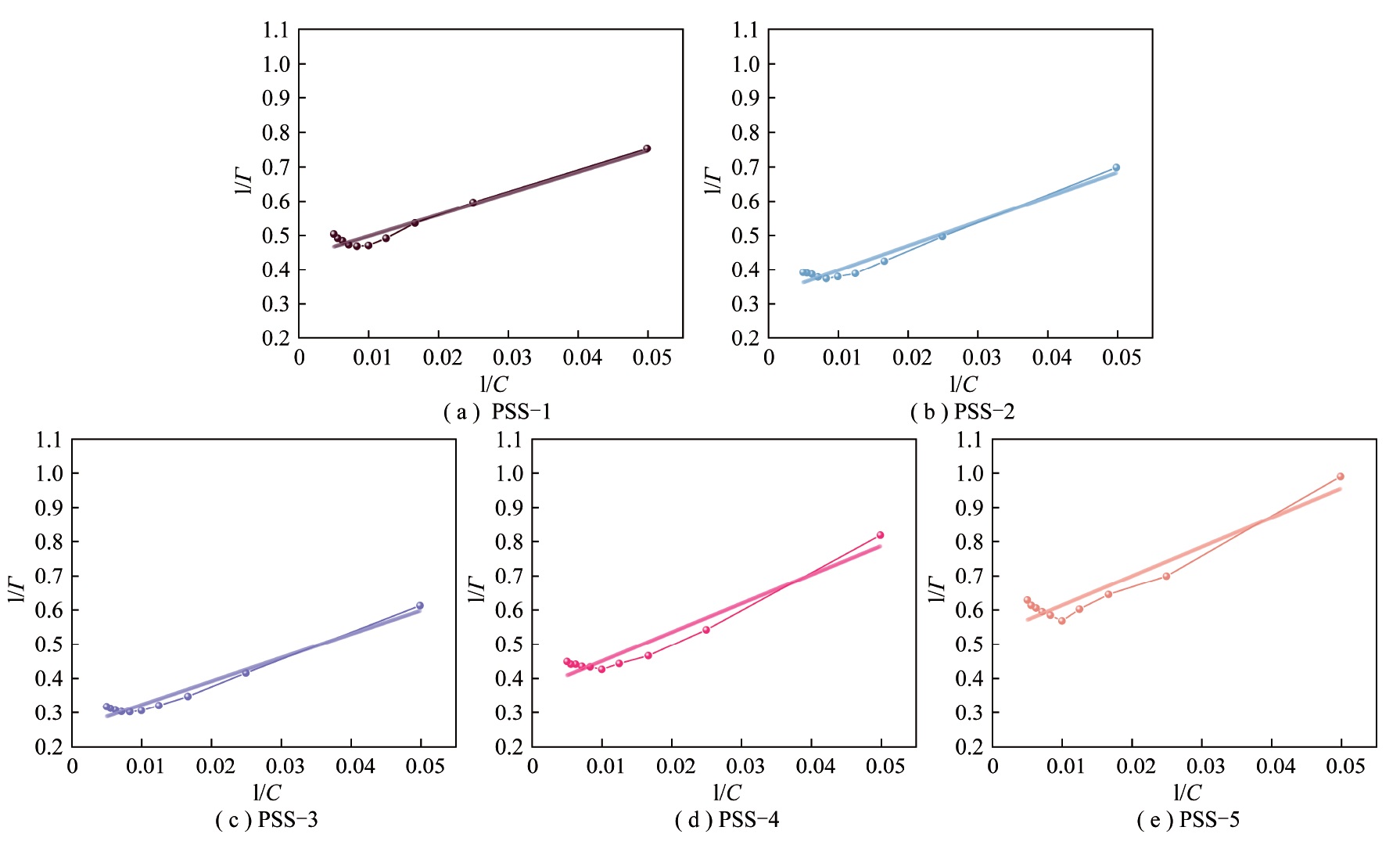

To improve the status quo of low slurry formation concentration and poor slurry performance of non-stick coal, Herein, Shenhua non-stick coal (SNC) was used as the object of study, and five kinds of sodium polystyrene sulfonate (PSS) dispersants with different lipophilic strengths were selected. The mechanism of the effect of the dispersant lipophilic groups on the slurry formation of SNC was investigated by examining the constitutive relationships between the strength of PSS lipophilic groups and the rheological properties, stability performance, wetting performance and adsorption behavior of SNC coal-water slurry. The results show that the strength of the lipophilic groups of PSS dispersants significantly affects the stability, rheology and apparent viscosity of the non-stick coal slurry. The longer lipophilic chain segments, the increases cross-linking between molecules and the larger spatial potential resistance formed make the slurry more stable. However, the apparent viscosity and rheology of coal-water slurry will be extremely high when the polymerization degree of PSS is 187 because the adsorption amount of dispersant molecules on the coal surface and its adsorption constant KL value increase and then decrease with the increase of PSS polymerization degree. SNC particle surface, which in turn forms uniform water molecule adsorption sites on the coal particle surface and promotes the formation of a uniformly textured hydration film.The SNC coal water slurry prepares with the dispersant content of 0.6% of dry coal powder and the slurry concentration of more than 61% has better slurry performance.

Effect of lipophilic groups of PSS dispersant on the slurry formation characteristics and surface adsorption behavior of non-stick coal

2023 No. 06

2023 No. 06

678

678 246

246

Authors:

- YE Zefu

- MENG Xianliang

- WU Guoguang

Unit:

- Shanxi Gemeng US-China Clean Energy R&D Center Co.,Ltd.,

- School of Chemical Engineering & Technology,China University of Mining & Technology

Abstract:

Keywords:

- PSS dispersant

- lipophilic group

- adsorption behavior

- coal water slurry

- slurry properties

Citation format:

叶泽甫(1980—),男,河南开封人,高级工程师,硕士。E-mail:yezefu2000@163.com

Chart:

Articles:

--

Citation format:

YE Zefu,MENG Xianliang,WU Guoguang.Effect of lipophilic groups of PSS dispersant on the slurry formation characteristics and surface adsorption behavior of non-stick coal[J].Clean Coal Technology,2023,29(6):180-188.

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors