Current situation and development trend of coal water slurry preparation technology

2023 No. 05

2023 No. 05

863

863 472

472

Citation format:

Authors:

- ZHANG Guoqing

- DU Shanzhou

- HUANG Yongbo

- ZHANG Daixin

- WEI Lubin

- HUANG Zhong

Unit:

- Department of Energy and Power Engineering,Tsinghua University

- School of Chemistry and Environmental Engineering,China University of Mining and Technology-Beijing

- Shenhua Zhungeer Energy Co.,Ltd.

Abstract:

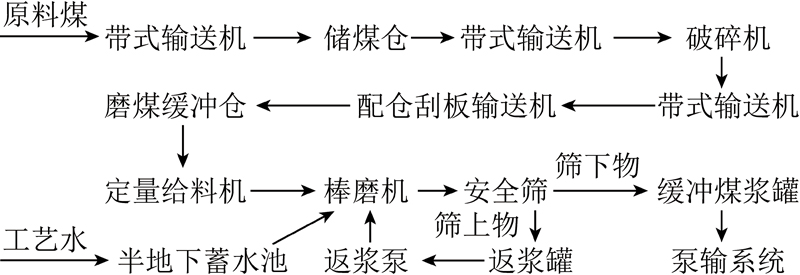

Preparation process is an important factor to determine the properties of coal water slurry, and then affect its storage, transportation and use. The latest research progress in the preparation process of coal water slurry was reviewed in recent years, including the preparation processes of different types of coal water slurry and the use of traditional Chinese medicine agent systems and particle size grading methods in the preparation process. Coal water slurry is divided into traditional coal water slurry and environmentally friendly coal water slurry according to the different raw materials used for slurry production. Traditional coal water slurry refers to the coal based components that are the main raw materials for slurry production, such as clean coal coal water slurry, low rank coal water coal slurry, and coal slurry water coal slurry. Environmentally friendly coal water slurry is a new way of resource utilization and comprehensive utilization of waste by blending raw materials such as biomass, industrial waste liquid, and solid waste, which can fully utilize the heat value contained in the waste and reduce disposal costs. The performance requirements of coal water slurry in application scenarios such as conventional boilers, circulating fluidized bed boilers, and gasifiers were analyzed and compared. Conventional boilers require low viscosity and fine particle size of coal water slurry, and the preparation process usually adopts a single stage grinding process. Circulating fluidized bed boilers, due to their unique suspended fluidized bed combustion method, relax the requirements for the particle size and viscosity of coal water slurry, which can reduce the consumption of high-density bed materials through non slag discharge operation, improve the inclusivity of ash content and ash melting point of raw coal for slurry production. Gasification requires higher performance of coal water slurry than combustion. The gasification furnace requires high slurry concentration and good reaction activity of coal water slurry, and to ensure good atomization effect, and the gasification of coal water slurry requires fine particle size and low slurry viscosity of coal water slurry particles. The development trend of coal water slurry preparation technology was prospected, and technical directions such as exploring low rank coal modification and upgrading methods, the influence of ultrafine particles on slurry properties, and expanding the types of slurry waste that can be mixed were proposed.

Keywords:

- coal water slurry preparation process

- traditional coal water slurry

- new coal water slurry

- boiler

- gasifier

Citation format:

Chart:

Articles:

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors