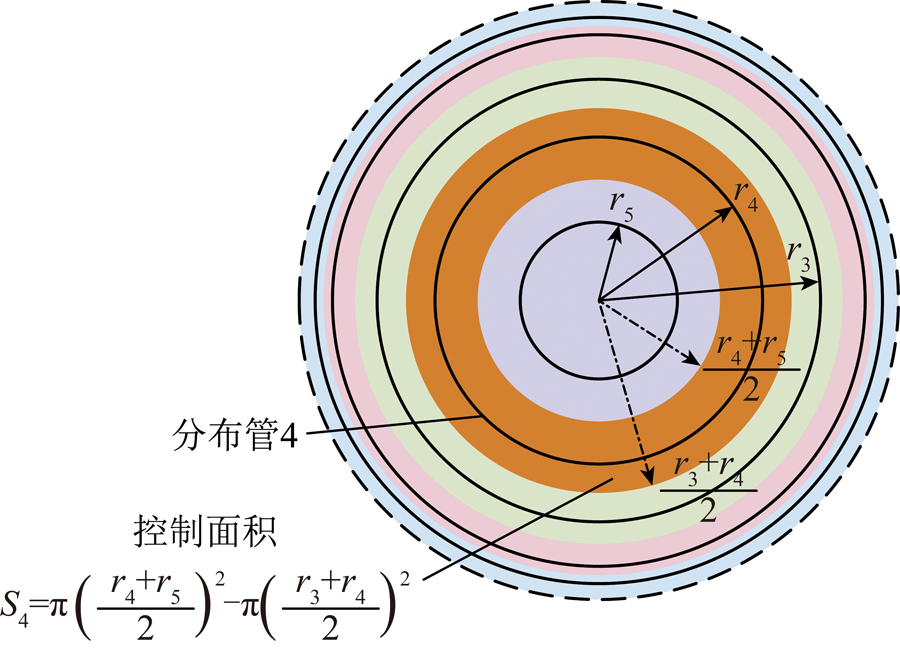

Gas distributor is one of the most important internals in Fischer-Tropsch slurry bed reactor,which can affect the hydrodynamics behavior and reaction performance of the reactor. In order to fully use the bottom head space of the slurry bed reactor,a muti-layer turbular slurry bed gas distributor was designed based on existing engineering experience. Under the given size and benchmark design conditions of the 5-layer gas distributor,computational fluid dynamics (CFD) was used to simulate and optimize the distributor structure. Firstly,the gas in the distributor could be treated as three-dimensional steady incompressible fluid. Since the outlet gas of the distributor was in turbulent state,the single-phase turbulence model SST-kω was selected to match the condition of curvature flow in the distributor. Then,the modeling was established based on the controling equations such as fluid continuity equation and momentum equation,the computational fluid dynamics software STAR-CCM+ was used to solve the above equations and the three-dimensional flow field of multi-layer gas distributor was numerically simulated. The results show that the benchmark design has the problems of bias and uneven flow distribution for a given 5-layer gas distributor. Finally,the nozzle parameters (length,radius and number) in each layer of the distributor were taken as the design variables,the gas distribution uniformity was taken as the objective function,and under the restrictive condition that the gas velocity at the outlet of the distributor nozzle was not higher than 75 m/s,the SHERPA algorithm was used to iterate 120 times for 15 design parameters,the range of 15 design parameters was covered in the optimization process. The results show that the optimization range of nozzle number is 9-15,the nozzle radius ranges from 9 mm to 14 mm,and the nozzle length is close to the upper limit of 150 mm to adjust the pressure drop through the fluid,overcome the static pressure difference of each layer of the distributor and make the gas evenly distributed among the annular distribution pipes of each layer. Moreover,the nozzle radius of the distributor should increase with the increase of layers,the number of nozzles must be coordinated with the radius and length of nozzles to achieve the optimal gas distribution performance. The final optimized distributor can obtain uniform and reasonable flow distribution without short circuit,the streamline is smooth without local vortex and other non ideal flow field.

CFD optimization of multilayer gas distributor in slurry bed reactor for Fischer-Tropsch synthesis

2022 No. 08

2022 No. 08

471

471 255

255

Authors:

- BU Yifeng

- PAN Teng

- MEN Zhuowu

- CHENG Youwei

Unit:

- National Institute of Clean-and-Low-Carbon Energy;College of Chemical and Biological Engineering,Zhejiang University

Abstract:

Keywords:

- gas distributor

- slurry bed

- turbulence model

- STAR-CCM+

- structural optimization

Citation format:

卜亿峰(1977—),男,河北张家口人,高级工程师,博士。E-mail:yifeng.bu@chnenergy.com.cn

Chart:

Articles:

--

Citation format:

--

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors