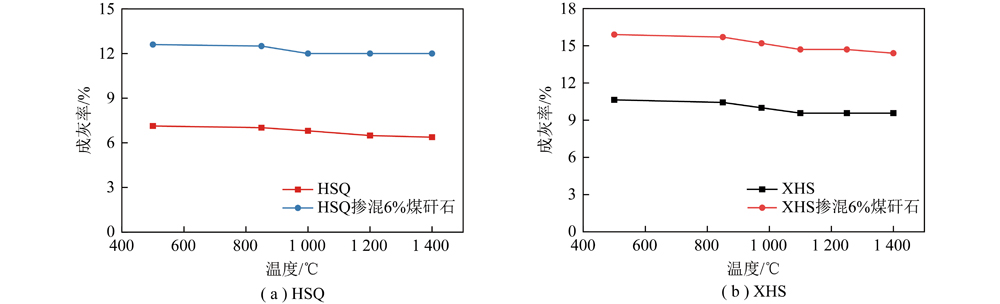

The coal resources in Zhundong area of Xinjiang is rich and easy to exploit. However, the high content of alkali metal (sodium) in Zhundong coal leads to serious fouling and slagging during combustion, which seriously restricts the large-scale utilization of zhundong coal. A large number of coal gangue will be produced in the mining and utilization of Zhundong coal. If it can be combined with Zhundong coal, it can not only solve the problems of coal gangue accumulation, occupation and pollution, but also make new contributions to the clean and safe utilization of Zhundong coal. Aiming at the fouling and slagging problems of Zhundong high-alkali coal, the effects of temperature and coal type on sodium release characteristics and the sodium capture effect of coal gangue additives were studied by comprehensively using TGA-DSC, XRD, XRF and other analytical methods. The results show that the amount of sodium released from ashed Zhundong coal at 500 ℃ increases with the rise of temperature. The two largest temperature ranges are 500-850 ℃(HSQ:24.62%,XHS:22.30%) and 1 200-1 400 ℃(HSQ:20.37%,XHS:49.09%). The sodium retention rate of HSQ blended sample at 850 ℃and 1 000 ℃ are increased by 22.60% and 19.23%, respectively, and sodium is immobilized in the ash in the form of K(Na,K)3Al4Si4O16 and NaAlSi3O8. The sodium retention rate of XHS blended sample at 850 ℃ and 975 ℃ is increased by about 15% relative to the original, and NaAlSiO4 and Na6(AlSiO4)6 are the main forms of sodium. Above 1 200 ℃, the Na in the two groups of samples is present as amorphous substances. The capture and release of sodium are carried out simultaneously, and the sodium content captured by coal gangue additives decreases with the increase of temperature, but at a high temperature of 1 400 ℃, the sodium content of the two Zhundong coal blended samples is more than twice that of the original sample, and still has a good sodium capture effect.

Sodium capture mechanism of Zhundong coal blended with coal gangue

2022 No. 07

2022 No. 07

484

484 531

531

Authors:

- XU Tianyao

- FU Peifang

- LIU Yang

- XIE Zihan

- XIONG Zhe

Unit:

- School of Energy and Power Engineering,Huazhong University of Science & Technology;State Key Laboratory of Coal Combustion,Huazhong University of Science & Technology

Abstract:

Keywords:

- Zhundong coal

- alkali metal

- coal gangue

- sodium capture

- sodium retention rate

Citation format:

许天瑶(1997—),男,江苏泰州人,硕士研究生。E-mail:xtyxtyyy@126.com

通讯作者:傅培舫(1964—),男,湖北仙桃人,教授,博士。E-mail:pffu@hust.edu.cn

通讯作者:傅培舫(1964—),男,湖北仙桃人,教授,博士。E-mail:pffu@hust.edu.cn

Chart:

Articles:

--

Citation format:

--

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors