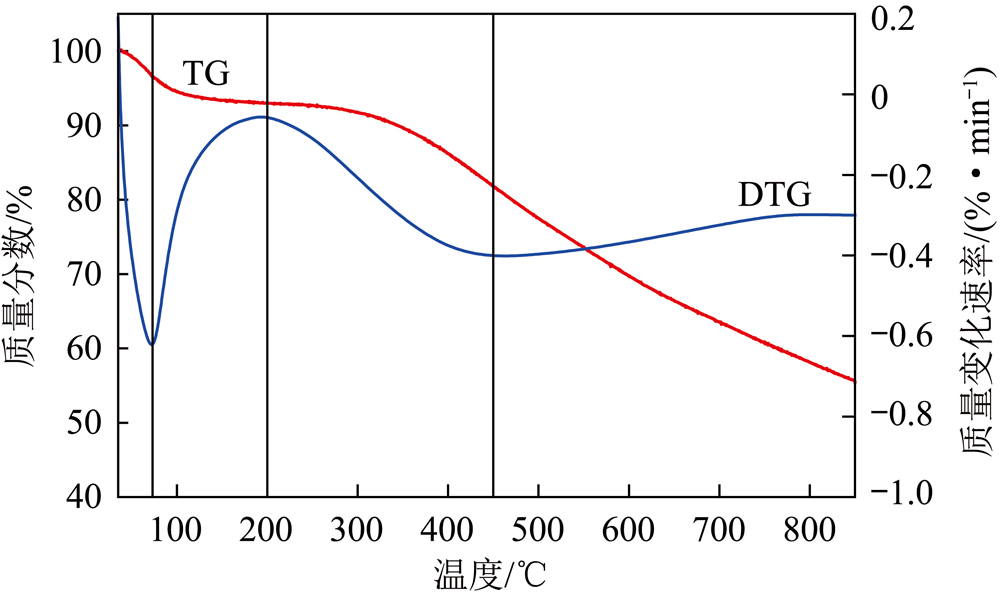

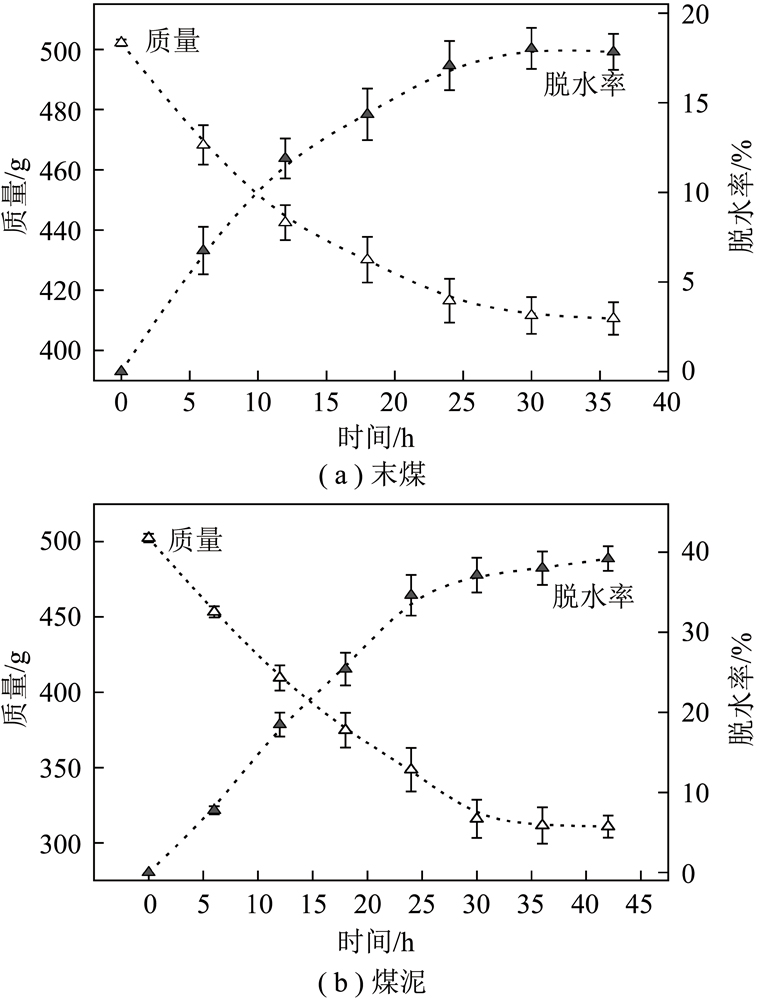

Coal is the main energy in China,which has greatly promoted the development of national economy. With the exploitation of high-quality coal,the content of fine coal and the difficulty of coal washing increase gradually. For the problem of low-quality coal (fine coal and slime) with high water content and low calorific value in coal preparation plant,the drying research was conducted by moisture meter,thermogravimetric-gas chromatograph-mass spectrometer instrument. The moisture occurrence characteristics and pyrolysis characteristics were examined,the temperature ranges for moisture removal were studied,and the best condition of low-quality coal drying was revealed. The decomposition temperature of coal was studied,and the pyrolysis process at different stages was revealed. The influence of vibration frequency on the separation effect of 6-0.5 mm coal was investigated by compound dry separator. The results show that for the fine coal and slime,the external water content are 17.84% and 39.20%,and the internal water content are 10.97% and 9.54%,respectively. The external water content of slime is higher than that of fine coal,and the internal water content is similar. The pyrolysis process can be divided into three stages. Water escapes before 101.9 ℃,and the critical temperature for the decomposition of macromolecules in coal is 305.7 ℃. For the 6-0.5 mm coal,when the vibration frequency of compound sparator is 36 Hz,the clean coal yield is 45.48% and the ash content is 10.36%, which effectively realizes the quality improvement and ash reduction of low-quality coal.

Water occurrence characteristics and dehydration of low quality coal and slime

2022 No. 07

2022 No. 07

680

680 680

680

Authors:

- ZHANG Jinlong

- FAN Youlin

- CHANG Ting

- YANG Fan

- YAN Guanghui

- ZHANG Bo

Unit:

- Shenhua Baotou Energy Co.,Ltd.,;School of Chemical Engineering & Technology,China University of Mining & Technology;Key Laboratory of Coal Processing and Efficient Utilization (China University of Mining & Technology),Ministry of Education

Abstract:

Keywords:

- fine coal

- slime

- drying

- low quality coal

- dehydration and quality improvement

Citation format:

张锦龙(1988—),男,陕西榆林人,工程师。E-mail:15149735907@163.com

通讯作者:张博(1989—),男,辽宁沈阳人,副教授,博士。E-mail:zhangbocumt@126.com

通讯作者:张博(1989—),男,辽宁沈阳人,副教授,博士。E-mail:zhangbocumt@126.com

Chart:

Articles:

--

Citation format:

--

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors