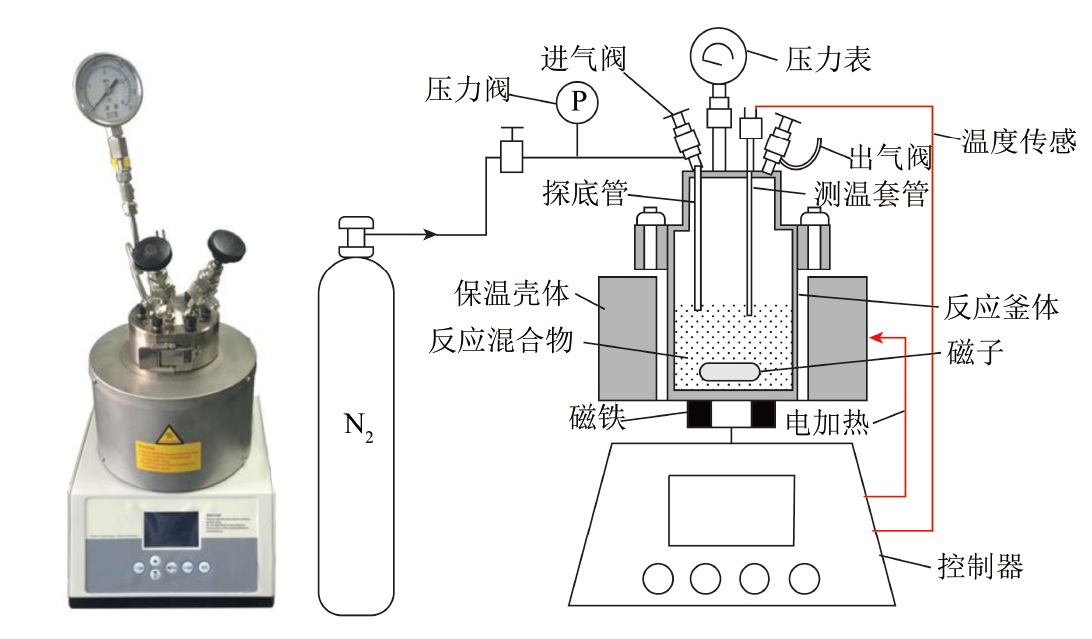

Licorice is the main component of traditional Chinese medicine prescriptions, and the amount of licorice residue produced has gradually increased with the development of the traditional Chinese medicine industry. However, the utilization of licorice residue is not ideal. Licorice contains a large amount of cellulose, hemicellulose and lignin, which is an excellent raw material for the preparation of activated carbon. The technical route of combined hydrothermal carbonization and chemical activation to prepare activated carbon can better pretreat the licorice residue with high water content, and conduct chemical activation to prepare activated carbon, which is an excellent way for efficient utilization of licorice residue. Using licorice as raw material, licorice was mixed with deionized water at a mass ratio of a ratio of 1∶8, and then hydrothermally carbonized at 210, 240, 270, and 300 ℃ respectively.And the hydrothermal carbon obtained by the hydrothermal carbonization reaction at 270 ℃ was activated with different chemical activators and at different activation temperatures, respectively. The results show that the sample has obvious functional group changes at 270 ℃, and it is believed that carbonization has occurred at 270 ℃. The activated carbon prepared by the combination of hydrothermal carbonization and chemical activation has a good pore structure.With KOH as a chemical activator,the activated carbon prepared under the condition of activation temperature of 700 ℃ has a specific surface area of 1 605.77 m2/g, a total pore volume of 0.890 4 cm3/g, an average pore size of 2.218 0 nm, and a methyl orange adsorption capacity of 184.5 mg/g.

Preparation of activated carbon from licorice by hydrothermal carbonization and chemical activation

2022 No. 06

2022 No. 06

553

553 466

466

Authors:

- HE Ziqian

- ZHOU Yabin

- ZHANG Cheng

- TAN Peng

- FANG Qingyan

- CHEN Gang

Unit:

- State Key Laboratory of Coal Combustion,Huazhong University of Science and Technology

Abstract:

Keywords:

- licorice

- hydrothermal carbonization

- chemical activation

- activated carbon

- adsorption

Citation format:

何梓谦(1998—),男,广东东莞人,硕士研究生。Email:heziqian@hust.edu.cn

通讯作者:张成(1980—),男,湖北武汉人,教授,博士。E-mail:chengzhang@mail.hust.edu.cn

通讯作者:张成(1980—),男,湖北武汉人,教授,博士。E-mail:chengzhang@mail.hust.edu.cn

Chart:

Articles:

--

Citation format:

--

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors