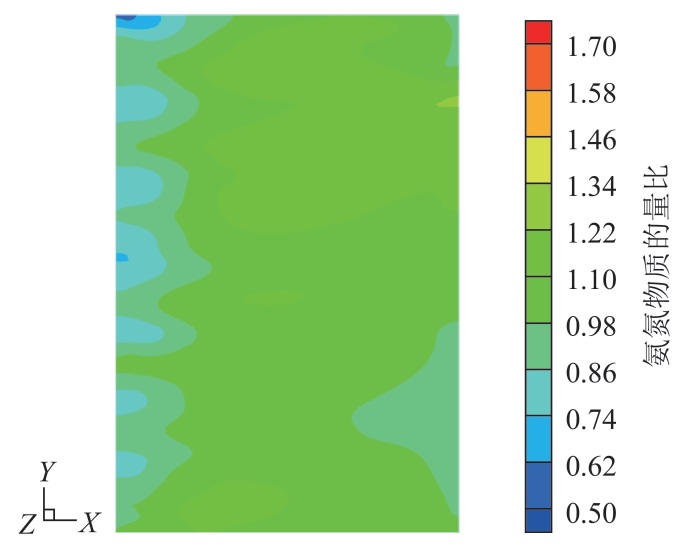

Under the requirements of ultra-low emission,the excessive injection of ammonia in the SCR DeNOx reactor not only affects the economy,but has also causes a series of operation and maintenance problems such as air preheater blockage,electrostatic precipitator fouling,and bag paste. In order to improve the uniformity of SCR inlet flue gas velocity and ammonia-nitrogen molar ratio,the computational fluid dynamics simulation and optimization research of flue flow field on one side SCR reactor of an old 300 MW unit in a certain power plant were carried out. Using Fluent as the main tool and based on the analysis of the empty tower model and the original deflector arrangement,the SCR flue deflector structure was optimized,and a static mixer was arranged downstream of the ammonia injection grid to achieve uniform cross-sectional velocity and ammonia-nitrogen molar ratio in the first layer of catalyst. The relative standard deviation of the velocity of the empty tower scheme is 26.1%,and the relative standard deviation of the ammonia-nitrogen molar ratio is 24.8%,all of which can not meet the engineering design requirements. In the original scheme,six groups of deflectors are set at the gradual expansion and corner of SCR flue,and the uniformity of speed and concentration is greatly improved,the relative standard deviation of the speed is 13.9%,which can meet the engineering design requirements,while the relative standard deviation of the ammonia nitrogen molar ratio is 15.3%,which can not meet the design requirements of less than 10%. The flow deflector arranged in the optimized scheme eliminates the vortex and reflux of flue gas at the flue corner and gradual expansion. Meanwhile,the static mixer is installed to enhance mixing,so that the relative standard deviation of velocity is reduced to 11.4%,and the relative standard of ammonia-nitrogen molar ratio to 9.4%. The uniformity of the flow field in the SCR flue has been greatly improved and the speed and concentration uniformity meet the design requirements. At the same time,the pressure loss of the optimized scheme is 706 Pa,which meets the B-level design requirements. The results show that the reasonable arrangement of the baffle and static mixer can improve the uniformity of the flow field without causing excessive pressure loss. The present work has reference value for the optimization of the on-site SCR flow field retrofit.

Flow field optimization of SCR-DeNOx system in a 300 MW coal-fired power plant

2022 No. 06

2022 No. 06

577

577 395

395

Authors:

- HUANG Jun

- LI Xinglei

- RUAN Bin

- LUO Sheng

- LU Zhimin

- YAO Shunchun

Unit:

- Guangzhou Zhujiang Electric Power Co.,Ltd.,;School of Electric Power,South China University of Technology;Guangdong Province Key Laboratory of Efficient and Clean Energy Utilization;Guangdong Province Engineering Research Center of High Efficiency and Low Pollution Energy Conversion

Abstract:

Keywords:

- SCR-DeNOx

- flow field optimization

- baffle

- ammonia-nitrogen molar ratio

- static mixer

Citation format:

黄俊(1988—),男,广东博罗人,工程师。E-mail:245582483@qq.com

通讯作者:姚顺春(1983—),男,浙江龙游人,教授,博士生导师,博士。E-mail:epscyao@scut.edu.cn

通讯作者:姚顺春(1983—),男,浙江龙游人,教授,博士生导师,博士。E-mail:epscyao@scut.edu.cn

Chart:

Articles:

--

Citation format:

--

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors