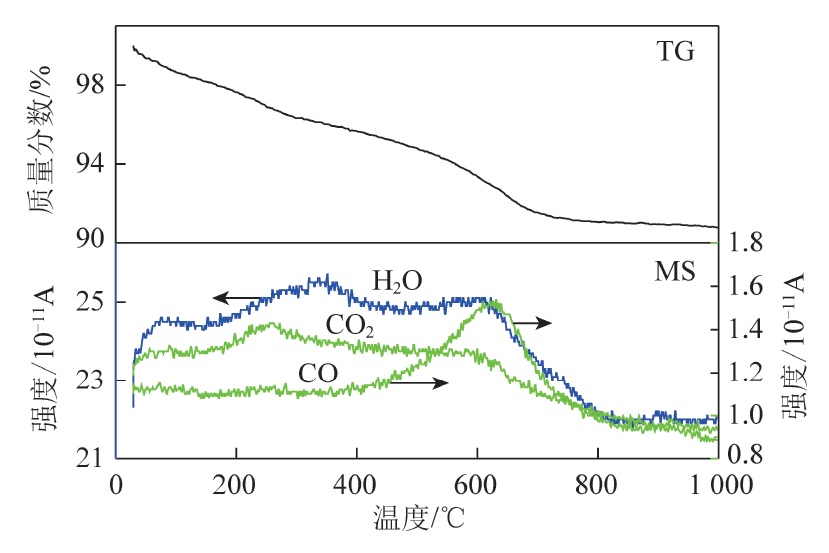

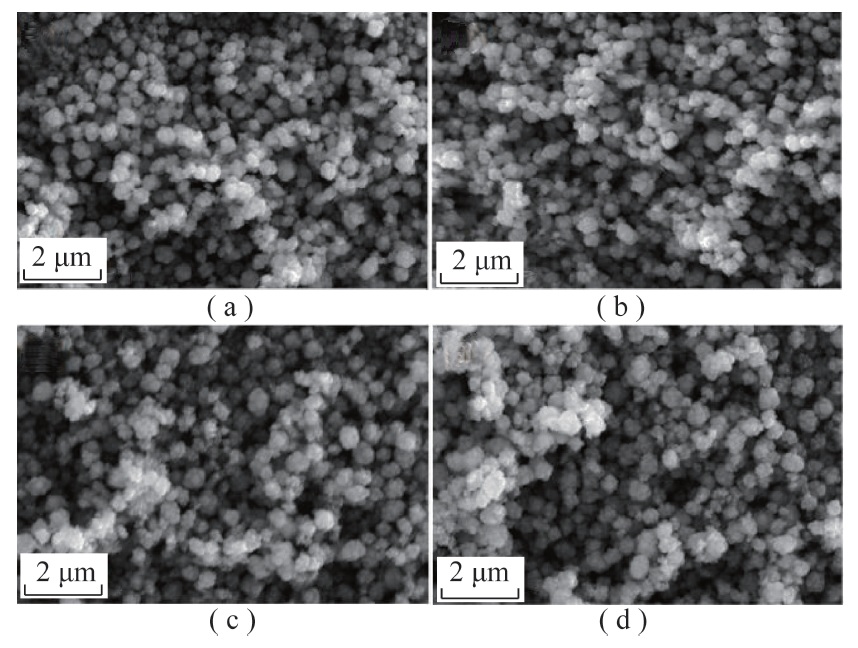

Supercapacitor is a new type of energy storage device,and electrode material as its key component has been attracting much attention,among which the modification treatment of electrode material is crucial for the research of high-performance supercapacitor.Coal-based capacitive carbon with high specific surface area (2 586 m2/g) was prepared with using Hebei anthracite coal as the precursor,KOH as the activator,alkali to coal mass ratio of 2∶1 and activation temperature of 800 ℃. The evolution of microstructure and surface chemistry of the capacitance carbon during hydrothermal reduction at different temperatures (600-1 000 ℃) and their effects on electrochemical properties were investigated by using coal-based capacitance carbon as raw material. The results show that with the increase of hydrothermal reduction temperature,the specific surface area of the samples first slightly increases and then gradually decreases,and the mesoporosity increases to different degrees compared with the original coal-based capacitive carbon. Among them,the samples obtained by hydrothermal reduction treatment at 700 ℃ have lower oxygen content (0.35%),stronger electrical conductivity,better wettability with organic electrolyte and higher degree of defects,and the electrochemical properties has been significantly improved:higher specific capacitance (179 F/g at 0.5 A/g current density),energy density (33.36 Wh/kg),power density (1 014.75 W/kg),multiplicative performance (58.7% capacitance retention at 5 A/g current density),and cycling stability (82% capacitance retention at 5 000 cycles). For coal-based capacitive carbon,hydrothermal reduction is a good modification treatment.

Effect of modification on structure and electrochemical properties of coal based activated carbon

2022 No. 04

2022 No. 04

1146

1146 773

773

Authors:

- ZHANG Zhaohua

- WANG Qian

- ZHANG Buqin

- ZHANG Fengmei

- ZHANG Chuanxiang

- HUANG Guangxu

- XING Baolin

Unit:

- College of Chemistry and Chemical Engineering,Henan Polytechnic University;Jizhong Energy Fengfeng Group Co.,Ltd.,

Abstract:

Keywords:

- supercapacitors

- coal-based activated carbon

- modification

- oxygen-containing functional group

- electrochemical propeties

Citation format:

张兆华(1994—),男,河南焦作人,硕士研究生。E-mail:zzh15239168493@163.com

通讯作者:张传祥(1970—),男,河南濮阳人,教授,博士生导师,博士。E-mail:zcx223@163.com

通讯作者:张传祥(1970—),男,河南濮阳人,教授,博士生导师,博士。E-mail:zcx223@163.com

Chart:

Articles:

--

Citation format:

--

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors