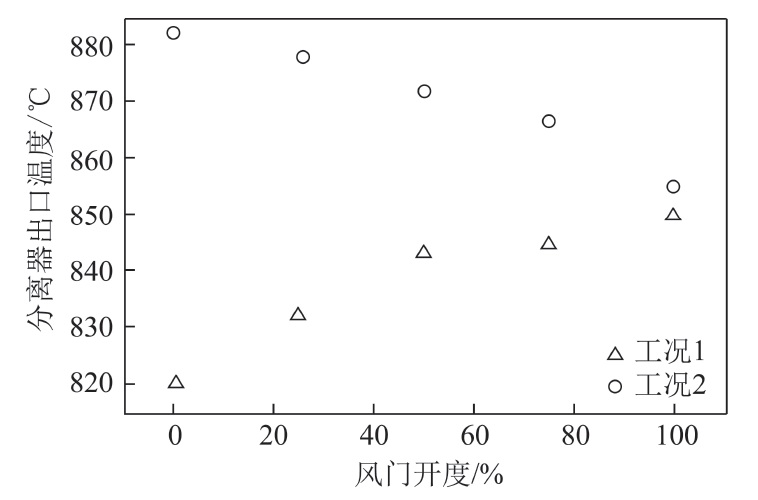

In order to improve the efficiency of SNCR denitrification and realize SNCR denitrification with wide load,a low nitrogen combustion adjustment test was carried out on a 130 t/h CFB boiler. Through the research on the temperature control mechanism of the separator,the influencing factors affecting the temperature of the separator were explored,and the control method of separator outlet temperature(Tsep)were studied. The results show that,there is a most efficient reaction temperature point Topt,in the SNCR temperature window. Higher SNCR denitration efficiency can be obtained by precisely controlling the Tsep around Topt. Flue gas recirculation (FGR) can adjust Tsep. FGR is put into operation at 130,90 and 70 t/h respectively,and the separator temperature is increased by 30,40 and 70 ℃. With the decrease of boiler load,the control ability of FGR to Tsep is enhanced. The ratio of upper and lower secondary air also also can adjust Tsep. By switching the upper and lower secondary air,The change range of Tsep is about 30 ℃. Tsep decreases with the increase of primary air rate,the adjustment range of Tsep is 18 ℃ at 4.5% oxygen content and the adjustment range of Tsep is 35 ℃ at 3.5% oxygen content,and the regulation range of primary air rate on Tsep is larger under low oxygen content. During the boiler load of 110-130 t/h,after the separator temperature is accurately controlled at (850±5) ℃,the 20% mass concentration of ammonia is reduced from 350 kg/h to 200 kg/h. The practical application shows that the separator temperature control technology can optimize the SNCR reaction efficiency at high load,and reduce the operation cost of denitration,restart the SNCR reaction at low load to achieve NOx emission standard,save 2.8 million yuan of ammonia cost.

Research and application of low nitrogen combustion adjustment technology based on reaction temperature control

2022 No. 04

2022 No. 04

899

899 381

381

Authors:

- SHI Bin

- DAN Zhenyu

- MOU Kehui

- LI Nan

- ZHAO Pengbo

- SUN Xianbin

Unit:

- Fenyi Power Plant,SPIC Jiangxi Electric Power Co.,Ltd.,;Huaneng Clean Energy Research Institute Co.,Ltd.,Beijing

Abstract:

Keywords:

- CFB boiler

- separator outlet temperature

- flue gas recirculation

- secondary air

- combustion adjustment

Citation format:

施斌(1981—),男,江西新余人,高级工程师。E-mail:34877011@qq.com

通讯作者:李楠(1984—),男,河南焦作人,高级工程师,硕士。E-mail:154405552@qq.com

通讯作者:李楠(1984—),男,河南焦作人,高级工程师,硕士。E-mail:154405552@qq.com

Chart:

Articles:

--

Citation format:

--

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors