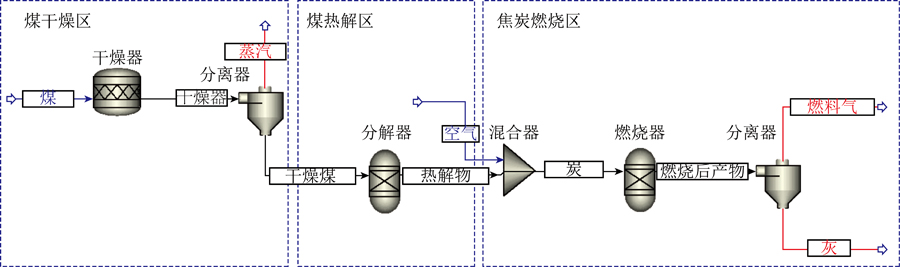

Circulating fluidized bed (CFB) has been widely used for the conversion of low-grade fuels such as gangue and sludge. In re⁃cent years, with the changes in the applications and requirements, extensive adaptive modifications have been made to the CFB. Accuratesimulation and prediction of the combustion performance inside the fluidized bed can provide fundamental support for these modifications.A fluidized bed model based on thermodynamics and kinetics was constructed to address the complexity of current fluidized bed models andthe difficulty of accurately predicting multiple parameters. The influence of fuel variation on the oxygen demand, as well as the variation ofvoid fraction and temperature with bed height were calculated. By constructing the thermodynamic model, the theoretical oxygen demandsfor four types of coal gangue with carbon contents of 74.05%, 17.71%, 24.27% and 34.01% were predicted, with theoretical oxygen de⁃mand of 15.17, 4.00, 4.47 and 6.20 kg/ h, respectively. The calculated results were related to fuel type and theoretical oxygen demand,which can assist in the design of parameters such as fan power and air volume. Furthermore, by embedding 10 RCSTR dynamic modules inseries into the kinetic model, the key parameters, including void fraction, temperature, and gas distribution, for different bed layerswere calculated,with the single-point parameter error of less than 15%. The classification and prediction of different types of static indica⁃tors can be achieved by the establishment of a multi process model fusion method, providing theoretical basis and design references for reg⁃ulating parameters such as fluidized bed air flow rate and primary-secondary air inlet positions during fuel transformation.

Prediction and optimization of decoupled combustion parameters in fluidizedbed air distribution based on multi-process model integration method

2023 No. 08

2023 No. 08

440

440 258

258

Authors:

- DI Zichen

- CHANG Chenggong

- YANG Fengling

- WU Haibin

- CHENG Fangqin

Unit:

- Institute of Resources and Environment Engineering, Shanxi University

- School of Environment,Tsinghua University

Abstract:

Keywords:

- Aspen Plus

- circulating fluidized bed

- parameter prediction

- thermodynamics

- kinetics

Citation format:

狄子琛(1992—),男,山西临汾人,讲师,博士。E-mail:dizichen@sxu.edu.cn

Chart:

Articles:

--

Citation format:

DI Zichen,CHANG Chenggong,YANG Fengling,et al.Prediction and optimization of decoupled combustion parameters influidized bed air distribution based on multi-process model integration method[J].Clean Coal Technology,2023,29(8):95-101.

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors