Removal process simulation on coal-pyrite of injection coal basedon column fluidized bed

2023 No. 12

2023 No. 12

547

547 310

310

Authors:

- YU Yanhui

- SHI Changliang

Unit:

- Department of Mechanical and Electrical Engineering,Yongcheng Vocational College

- College of Chemistry and Chemical Engineering,Henan Polytechnic University

Abstract:

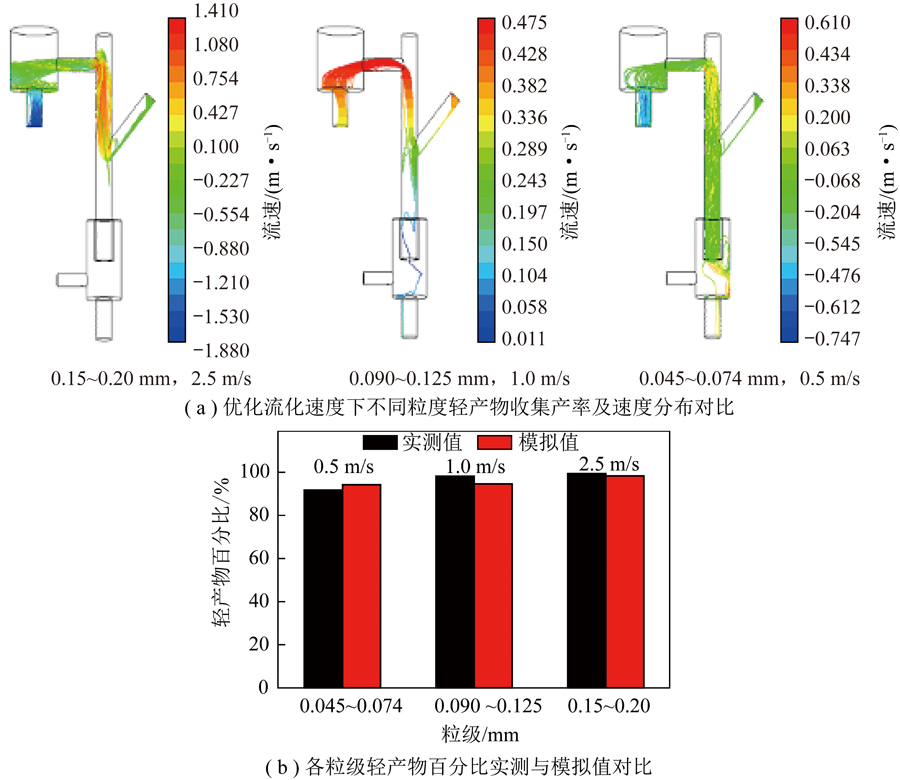

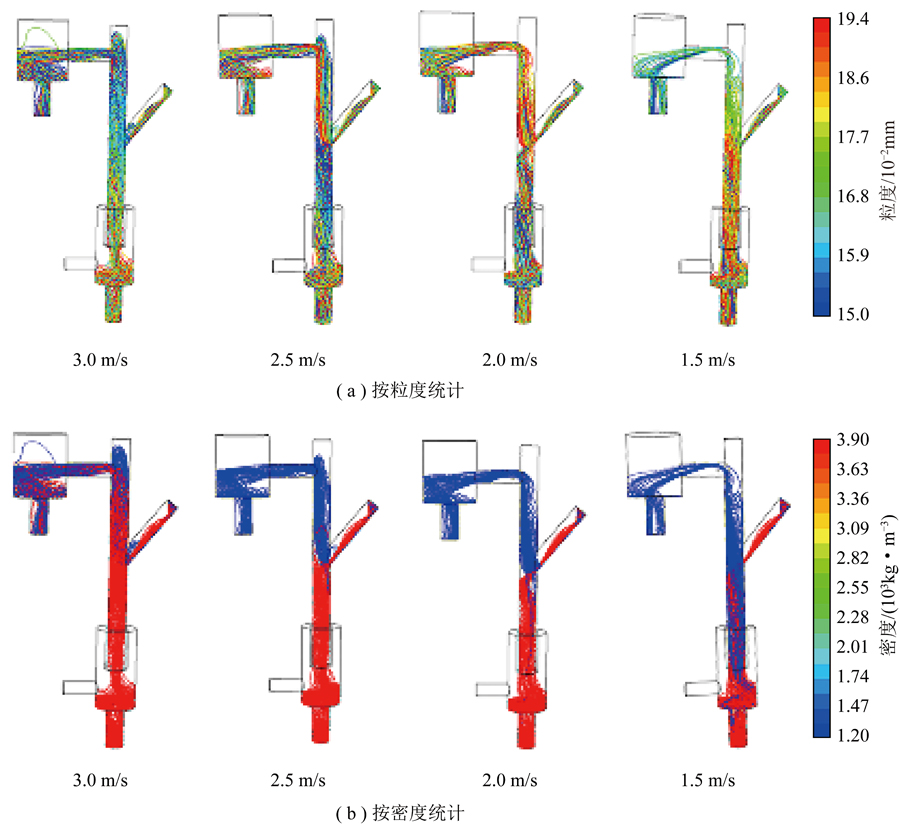

The pyritecontent in the returned powder of coal millcan be effectively reduced and the SO2 environmental pollution can be reduced due to high-gradient magnetic separation technology, as the embedded combination in the coal injection combustion system. Also,the pre-removal efficiency of coarse coal powder classifier is an important factor affecting the quality of magnetic separation and powder recovery. Coal-pyrite and coal-matrix were selected as mixed simulation samples. Based on a self-made column fluidized bed, the particles motion characteristics were simulated under the influence of particle size, fluidization speed and mixing ratio. The results show thatthe fluidization velocity is relatively uniform in column fluidized bed, and there are primary and secondary mismatching zones in the separation zone. In the actual separation process, the particles motion characteristics of each particle size are completely different. The increaseof the particle size corresponds to a decrease response of the fluidization velocity. The simulation yield of coarse coal-matrix is 99.4%, andthe yield of fine coal-matrix is 91.7%. The fine particles are obviously difficult to handle under different conditions, so the over-grindingphenomenon in the front section should be avoided. The loss of the coarsecoal - matrix in the heavy products and the entrainment offine middling coal pyrite in the light products are the main reasons for the low separation efficiency of fluidized bed. Also, with the increase of the proportion of coal-pyrite, the movement characteristics of coarse particles do not change significantly, and the mixed materials in the medium particle size show a phenomenon of material return in the secondary mismatch zone of the sorting area. The comparisonseparation experiment under the simulation parameters was further carried out. The sulfur content of the enriched light products is greatlyreduced at the optimal simulation parameters, and the experimental yield is close to the simulated yield. The research results are of positive significance for improving the coal injection combustion efficiency and finally reducing coal pollution.

Keywords:

- coal-pyrite

- coal-matrix

- column fluidized bed

- pre-removal

- particles dynamics

Citation format:

于艳辉(1982—),女,河南永城人,讲师,硕士。E-mail:yuyanhui0106@126.com

Chart:

Articles:

--

Citation format:

YU Yanhui,SHI Changliang.Removal process simulation on coal-pyrite of injection coal based on column fluidized bed[J].Clean Coal Technology,2023,29(12):119-127.

-

Executive director

China Coal Science and Industry Group Co., Ltd

-

Sponsored by

Coal Science Research Institute Co., Ltd

Coal Industry Clean Coal Engineering

Technology Research Center -

Editor in Chief

XIE Qiang

-

Vice Editor-in-Chief

YU Chang

SHI Yixiang

ZHAO Yongchun

DUAN Linbo

CAO Jingpei

ZENG Jie -

Publication Frequencies

Monthly

-

ISSN

1006-6772

-

CN

11-3676/TD

Covered by

- CSTPCD

- RCCSE(A+)

- AJ

- EBSCO host

- Ulrichsweb

- JST

- Scopus

Contact us

New Media

-

Meichuanmei

Meichuanmei -

Clean Coal Technology

Clean Coal Technology -

Online Journals

Online Journals

Submission system

Submission system Copyright agreement

Copyright agreement Instructions for authors

Instructions for authors